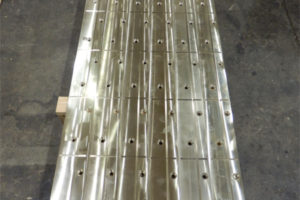

Magnesium Bronze Liners

A customer in the steel industry contracted us at American Precision Services to create the liners as highlighted below. Utilizing our advanced CNC milling machine, magnesium bronze material was manipulated to meet the specified contours, with the completed unit measuring 8’5” in length, 5” in width, and a height of 0.75”. The tightest tolerances of +0.001/-0” was met during production. Flame hardening was also employed for increased wear resistance and less distortion, and the unit was also deburred to smooth and remove manufacturing debris.

The liner was left with a raw finish, and received comprehensive inspections including visual, dimensional, and magnetic particle inspections to ensure quality and integrity. Thirteen liners were produced within a turnaround time of 30 days, shipped to the customer in East Chicago, IN. For more details about this custom magnesium bronze liner construction, or the other precision milling and machining capabilities available please see the table below or contact us directly.