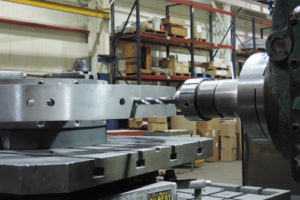

American Precision Services is equipped to manage your conventional machining requirements for components of most any size. Inside of our large, modern facility, you will find our expert technicians executing a full range of machining techniques on our 3-axis vertical and horizontal boring mills, engine lathes, key seaters, verticals mills, and drill presses. In addition to milling, drilling, and turning, they are able to achieve complex profiles, deep pockets, and countersunk holes, and knurled surfaces with short cycle times and tight tolerances. A large 120″ x 60″ x 60″ work envelope, along with a turning capacity of 9’ in diameter, enables us to fabricate parts weighing up to 10 tons. We are capable of working with many materials, including most metals as well as UHMW and engineered plastics.

Quality management is a top priority. We carry out dimensional inspections and material property testing throughout the manufacturing process to validate component integrity. We are very flexible, and can easily adjust schedules and equipment usage to meet changing production demands. Deadlines are taken seriously and met with responsibility. Our goal is to develop a partnership with our customers to ensure their every need is met.

Please contact us today to learn how our machining services can benefit your next project.

Past Projects

Conventional Machining Capabilities:

- Conventional Machining Processes

-

Milling

Drilling

Boring

Turning:- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

Threading

- External

- Internal

Tapping

Thread Milling

Knurling

Counterboring

Countersinking

Pocketing

Profiling

Reaming

Parting/Cutting

Facing

- Machinery Axis

-

3

- Equipment

-

Vertical Boring Mills

Horizontal Boring Mills

Engine Lathe

Key Seater

Vertical Mills

Drill Press

- Materials (Metals)

-

Steel

Stainless Steel

Aluminum

Titanium

Bronze

Brass

Copper

Hastelloy

- Materials (Plastics)

-

UHMW

Delrin

- Milling Length

-

Up to 120 in

- Milling Width

-

Up to 60 in

- Milling Height

-

Up to 60 in

- Turning Diameter

-

Up to 9 ft

- Maximum Part Weight

-

Up to 20,000 lbs

- Inspection

-

Dimensions

- Testing

-

Hardness

Hydro

- Additional Services

-

Chemical Cleaning

Sand Blasting

Painting

- Production Volume

-

Short and Long Run

Prototype to Medium Production

- Typical Lead Time

-

Flexible Delivery Schedules

Additional Information

- Industry Focus

-

Industrial

Steel

Food

Paper

Construction

Energy

Chemical

Water Treatment

Railroad

- Intended Applications

-

Parts

Components

Pumps

Turbines

Blowers

Compressors

Gear Boxes

Processing Equipment

- File Formats

-

AutoCAD

SolidWorks

MasterCAM